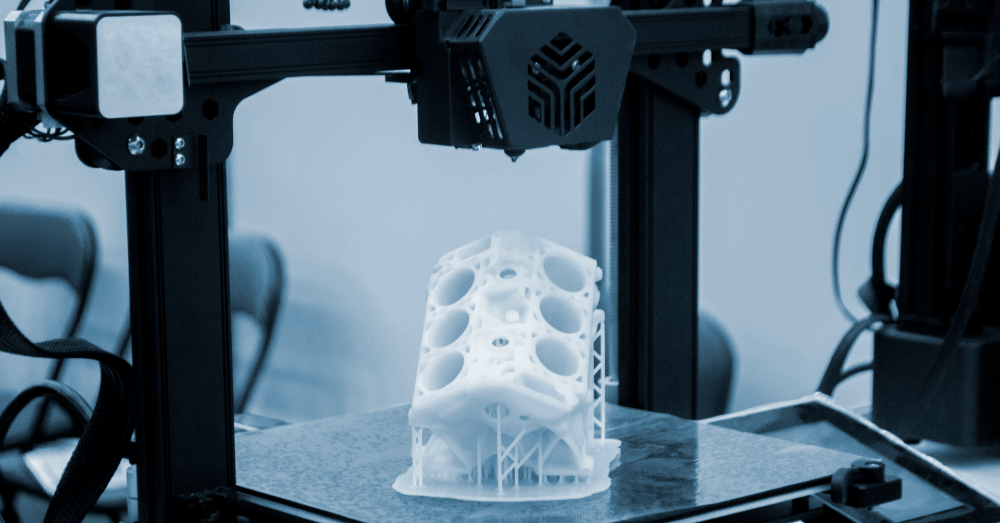

One of the most incredible new technologies is 3d printing. Many automakers now make 3D-printed car parts and use this tech for other applications as well.

The most widely used purpose of 3d printing in any industry is prototyping. Once a design is entered into a computer, the printer can produce the item, which makes it much easier for the company to test the product. Using this technology for prototyping in the automotive industry doesn’t mean the printer can produce an entire car in one run, but it can produce some parts that can be tested and quickly perfected.

Here are several ways automakers are utilizing 3d printing.

Lightweight car parts

Some companies have found that the 3D-printed car parts they produce are much more lightweight compared to parts made of metal. This means automakers can create lighter parts by using multi-material architecture that blends various materials together. If race teams or automakers were looking for ways to make parts lighter and shave a few pounds off of high-performance cars, this could be the way to make that happen without too much trouble.

Concepts on a large scale

Some automakers, such as Volvo, Nissan, Lotus, McLaren, Geely, and Tata, have turned to Vital Auto to take sketches and designs to create fully realized physical prototypes of vehicles using 3d printing. This is a huge part of the manufacturing process within this company, giving these automakers the physical cars they want to see much faster than if they made the prototype vehicle through more traditional methods. Vital has its printers running all the time and has utilized this technology since the beginning of its entry into the automotive industry.

Better parts

Some of the most impressive 3D-printed car parts are made of high-performance materials that can be added by the manufacturer. These parts are tested to stand up to the challenge of extreme environments. Some automakers also use this process to build parts for the tools they use to make car parts. This is a new and more dynamic method of creating machine parts and car parts. This printing process aids manufacturing to reduce overhead and increase efficiency by making custom jigs and fixtures and creating low-volume rapid tooling for the manufacturing process.

Making the molds and dies

Many car parts are still stamped out of steel and aluminum, which means a die or mold must be created to allow this to happen. This is another great use of 3d printing in the automotive industry. These molds also work for stamping materials, such as the seat upholstery of a vehicle. This ensures the stamped logo on a headrest will remain intact for many years. The finished products can be stretched over the part of the car once the stamping process is complete.

Aftermarket parts

If you’re familiar with the Ford Maverick, you might also be aware of the FITS system available in this compact pickup truck. This system allows owners to order and install up to eight different 3D-printed car parts that can be added to the interior of the vehicle to improve the cargo spaces and make the cabin more livable. This was the first time such a system was used by a major automaker, and it opened the door for other 3D-printed parts. Many aftermarket parts companies make parts for various vehicles using this same process.

Engine performance improved

Instead of utilizing the standard setup for a specific engine part, automakers and motorsport teams can use this printing process to create new and better parts to improve engine performance. An example of this occurred when Forge Motorsport created an improved inlet duct design for the airflow in the Toyota GR Yaris. They reverse-engineered the part through 3D scanning and designed a new part that was then tested and perfected for the car. This new airbox location opening improved the performance of this new hot hatch.

3D-printed car parts are becoming more commonplace and useful across the entire automative industry. Will there be a time when an entire vehicle is produced using 3d printing?

This post may contain affiliate links. Meaning a commission is given should you decide to make a purchase through these links, at no cost to you. All products shown are researched and tested to give an accurate review for you.